As a common storage facility, silos are widely used in agriculture, food processing and chemical industries. To ensure the safe, stable and efficient operation of silos, the design and implementation of its construction scheme is very important. This paper will introduce a typical silo construction

READ MORE

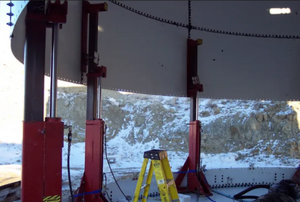

A. Technical introductionThe pump station is composed of fuel tank, motor, high pressure oil pump, adjustable relief valve, three-position four-way solenoid valve, pressure gauge and so on.Start the motor, the high pressure oil pump starts to supply oil, the system pressure is adjusted by the adjust

READ MORE

The hydraulic station is composed of oil tank, air filter, level gauge, integrated block group, control box, pump group and synchronous cylinder.Effective volume of oil tank 240L; The function of the air filter is to filter the debris in the air;The integrated block group is the compact installation

READ MORE

Step 1: Remove the hydraulic jacks and supportStep 2: Load the hydraulic jacksStep 3: Tighten the bolts and nuts Step 4: Remove the base plate and bolts Step 5: Install the baseplate Step 6: Install the cable-stayed plate Step 7: Install the first square tube Step 8: Install the second square t

READ MORE

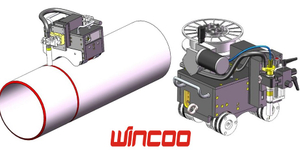

The solution of container tube coil production line is to prepare the installation. It is less difficult to prefabricate, so try to make pipe sections that can be prefabricated on the floor, which can speed up construction progress and reduce construction difficulties.

READ MORE

Solution of container pipe spool fabric line refers to pipeline design, prefabrication management, pipeline cutting, pipeline groove processing, welding, logistics, anti-corrosion paint, pipeline flaw detection and other work in a fixed area.

READ MORE

Containerized pipe spool fabrication solution is to carry out pipe design, prefabrication management, pipe cutting, pipe groove processing, welding, logistics and anti-corrosion paint, pipe flaw detection and other work in a fixed area.

READ MORE

The whole pipeline project is divided into solution of container pipe spool fabrication line, on-site prefabrication and on-site installation. Among them, the Solution of container pipe spool fabrication line is the first step of pipeline engineering, and its importance is self-evident.

READ MORE

Solution of container pipe spool fabrication line refers to a construction process in which some pipe sections with a determinable or adjustable size in the single-line diagram are concentrated in the specified area in the early stage, and they are assembled, welded, and tested.

READ MORE

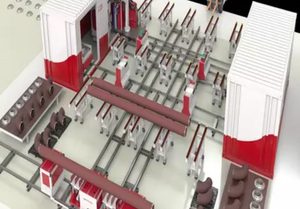

Pipe Spool Fabrication Line have seven steps:blasting→cutting→beveling→fitting-up→welding→non destructive testing→paint spraying.1. Blasting machine We need know the size,the weight,the material and clean level of the workpiece.Then we can offer suitable machine to you.

READ MORE

The following short description gives the working procedure in outline. It can in certain details be modified when required.Step 1. The tank bottom – plates are placed on the prepared foundation and welded together.Step 2. The beams or lattice work of the roof are assembled and finally joined to the

READ MORE

Manufacturing step:1.Laying-off;2.Fitting-up;3.Welding;4.Correcting;5.Paint spraying;6.PackingI.Laying-off processLaying-off is the processing of steel plates or sections into the parts or components required by the drawings.1. Steel plate laying-off: first is to find 90 degrees, and then draw th

READ MORE

I.Introduction Plate rolling machine is a forging and pressing equipment.Plate rolling machine is mainly used in the field of cold machining of industrial containers and pressure tanks, etc.Required molding consistency, arcs are standard, good welding seam connection.Traditionally, industrial

READ MORE

With the progress of society and the development of economy, people's demand for resources is increasing.From cars that need diesel to power plants that need oil.In short, oil, natural gas and other resources have become indispensable in daily life.But conventional rail and cruise transport is slow

READ MORE