| Availability: | |

|---|---|

| Quantity: | |

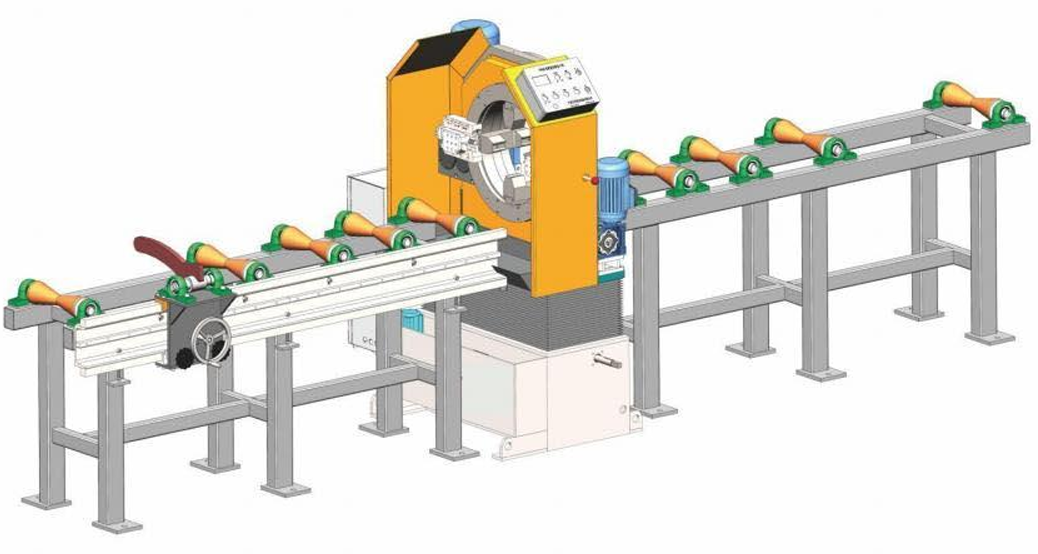

PCM 6~36

WINCOO

The PCM series pipe cutting beveling machine has super or economy, practicality and reliability, compact structure design, simple and convenient operation, both to meet the factory fixed operation and convenient construction site mobile operation, after continuous upgrading and optimization, the series of products have been updated to the fourth generation, while the equipment has a perfect product series, covering the processing pipe diameter from 34 mm to 930 mm ; The processing form adopts pipe clamping and not moving, and the cutter head drives the tool holder to rotate to realize mechanical ratchet feed, which is mainly used for cutting and beveling of pipelines. It can be cut off and beveled at any position in the middle of the pipeline at the same time, or it can be cut off only for the pipeline alone or only for the pipe end alone.

Product Parameter

| Model | PCM-6 | PCM-12 | PCM-16 | PCM-18 | PCM-24 | PCM-36 |

| Applicable pipe diameter | DN30-150 | DN40-300 | DN80-400 | DN250-500 | DN300-600 | DN600-900 |

| Applicable material | Carbon steel, alloy steel, stainless steel, duplex stainless steel, low temperature steel, heat resistant steel, etc | |||||

| Wall thickness | Stainless steel/alloy steel 3-25 mm, carbon steel 3-30 mm | |||||

| Processing efficiency | According to the calculation of pipe wall thickness, the feed speed is about 2 mm/min.With the diameter of 219*8 mm pipe as an example, the time of cutting + beveling is about 4 min | |||||

| Clamping system | One set of cutting tool holder, one set of beveled tool holder | |||||

| Tool holder | Equipped with electric lifting stand, to meet the processing of different pipe diameters for the height of the host electric lifting adjustment | |||||

| Cold cutting method | Circulating water cooling | |||||

| Feed amount | 0.1~0.2 mm/r | |||||

| Beveling type | I/V/ double V type (standard 0* cutting knife and V type 30* beveling knife) | |||||

| Accuracy of beveling surface | Verticality of beveling end s1mm; finish sRa6.3, Angle deviation s0.5° | |||||

| Feed mode | Rotary radial automatic feed, pipe clamping is not moving, cutter head electric rotation, the tool layer into the feed | |||||

| Operation mode | Control box switch button, easy to operate | |||||

| Height adjustment | According to the calculation of pipe wall thickness, the feed speed is about 2 mm/min.With the diameter of 219*8 mm pipe as an example, the time of cutting + beveling is about 4 min | |||||

| Optional accessories | □Pipe manual delivery roller table □Electric tube conveying roller table □Mechanical fixed length mechanism | |||||

Product Advantage

The cutting and beveling process can be completed on one machine. Compared with the traditional method where the pipe is first cut by a cutting machine and then moved to a beveling machine for processing, this method saves one processing step. The pipe does not need to be transported between the two machines, reducing the number of operators and the space required for the factory layout, significantly improving efficiency and saving operating costs.

Major Component

Product Photos

Sign up for our newsletter to receive the latest news.

Copyright © 2020 WINCOO ENGINEERING CO.,LTD

Support By:Leadong