| Availability: | |

|---|---|

| Quantity: | |

PAM 6~32

WINCOO

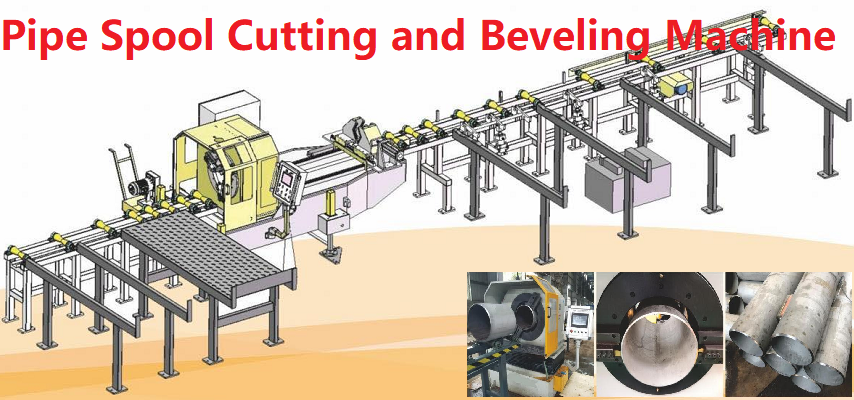

PAM series CNC pipe cutting beveling machine is a fully automatic CNC special machine tool for pipe cutting beveling processing. It is an economical product developed by our company on the basis of CTA series cutting beveling machine to meet the needs of different users and different uses. it is especially suitable for fast cutting and bevel processing of medium and thin wall pipe. It adopts pipe clamping without moving knife for machining, realizes CNC automatic control of machining process through PLC control system, and finishes the presetting,storage and call of machining program by man-machine interface. It is an advanced and efficient pipe cutting bevel processing equipment at home and abroad.

Product Parameter

| Model | PAM-6 | PAM-12 | PAM-16 | PAM-24 | PAM-32 |

| Applicable pipe diameter | DN30-150 | DN40-300 | DN50-400 | DN300-600 | DN500-800 |

| Applicable material | Carbon steel, alloy steel, stainless steel, duplex stainless steel, low temperature steel, heat resistant steel, etc | ||||

| Wall thickness | Stainless steel, alloy steel: 2-20 mm, carbon steel: 2-25 mm | ||||

| Processing capacity | Straight cutting machining, end bevel machining, cutting + single bevel machining | ||||

| Processing tool holder | one set of cutting tool holder, one sets of beveled tool holder | ||||

| Clamping system | An electric multi-claw self-centering clamping system is installed on the main engine body together with the cutter head | ||||

| Stand lifting | Equipped with electric lifting stand, to meet the processing of different pipe diameters for the height of the host electric lifting adjustment | ||||

| Advance and retreat tool mode | Servo motor precisely controls the tool fast forward, work forward, empty knife, fast back, etc.. with the function of coordinate memory | ||||

| Processing efficiency | Taking Ф219*8mm pipe as an example, the time to cut off + double beveling is about 2min | ||||

| Load feed | 0.05-0.5mm/r | ||||

| No load | < 300mm/min | ||||

| Cold cutting mode | Water cooling or air cooling ofcutting fluid circulation | ||||

| Operation control | PLC program control +10 inch man-machine interface | ||||

| Intelligent processing | Super software capability, the database can search and automatically match the processing process, after selecting the processing material and entering the pipe diameter and wall thickness, the system can automatically match the appropriate processing parameters to prevent misoperation | ||||

| Machining accuracy | verticality of beveling end face<=1 mm,Finishi<=Ra6.3, Angle deviation<=0.5'' | ||||

| Host selection | □ PAM standard host □ AM with integrated tail seat fixed length host | ||||

Product Advantage

Major Component

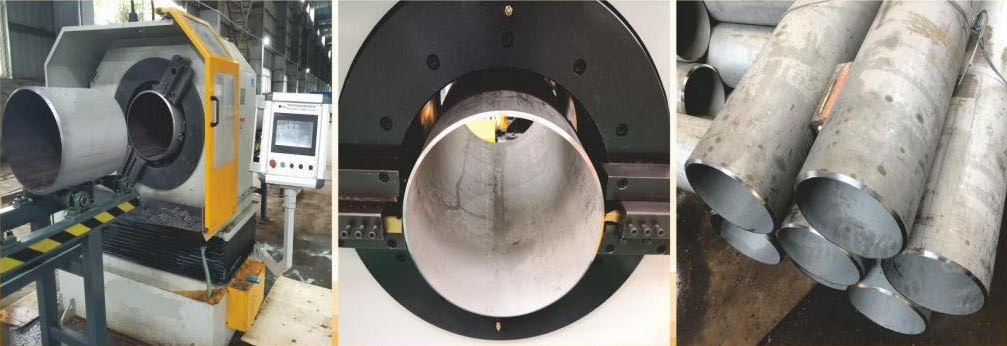

Product Photos

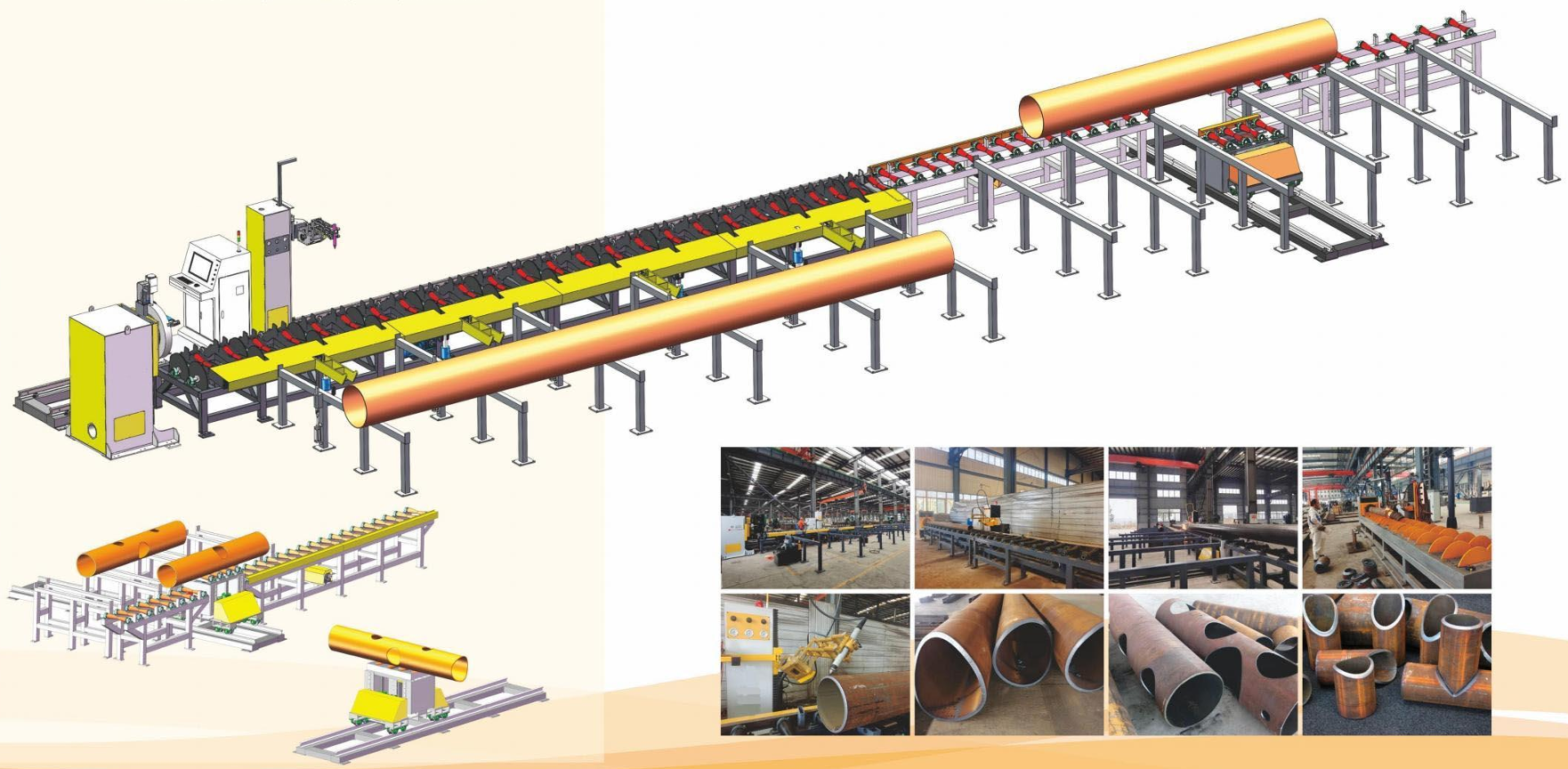

Precision Engineered Pipe Spools: Elevate Quality & Reduce Rework with Advanced Prefabrication Lines

What is the significance of the solution of container pipe spool fabrication line?

What is the meaning of the solution of container pipe spool fabrication line?

What do you know about containerized pipe spool fabrication solution?

How can we take solution of container pipe spool fabrication line?

What are the application areas of the solution of container pipe spool fabrication line?

What are the troubleshooting methods for pipe spool fabrication line?

Sign up for our newsletter to receive the latest news.

Copyright © 2020 WINCOO ENGINEERING CO.,LTD

Support By:Leadong