Compared with other structural engineering, steel structure engineering has the characteristics of high material strength, good seismic performance, high degree of industrial production, good airtight performance, safety and reliability.These determine the steel structure in some large height or span of the structure, load or crane lift a large weight of the structure, a large vibration structure, high temperature workshop structure, high sealing requirements of the structure, the requirements of activity or often assembled and disassembled structure, bridge structure is widely used.It can be seen that the development prospect of steel structure is broad.

The following is the production process of steel structure:

Lofting is a process in the production process of steel structure, only the lofting size is accurate, in order to avoid the accumulation of errors in each subsequent processing process, to ensure the quality of the whole component.

The cutting methods of steel blanking include cutting, punching, sawing, gas cutting, etc. Which method should be used in construction according to the specific requirements and actual conditions to determine. After cutting the steel shall not be stratified, there shall be no cracks on the section.

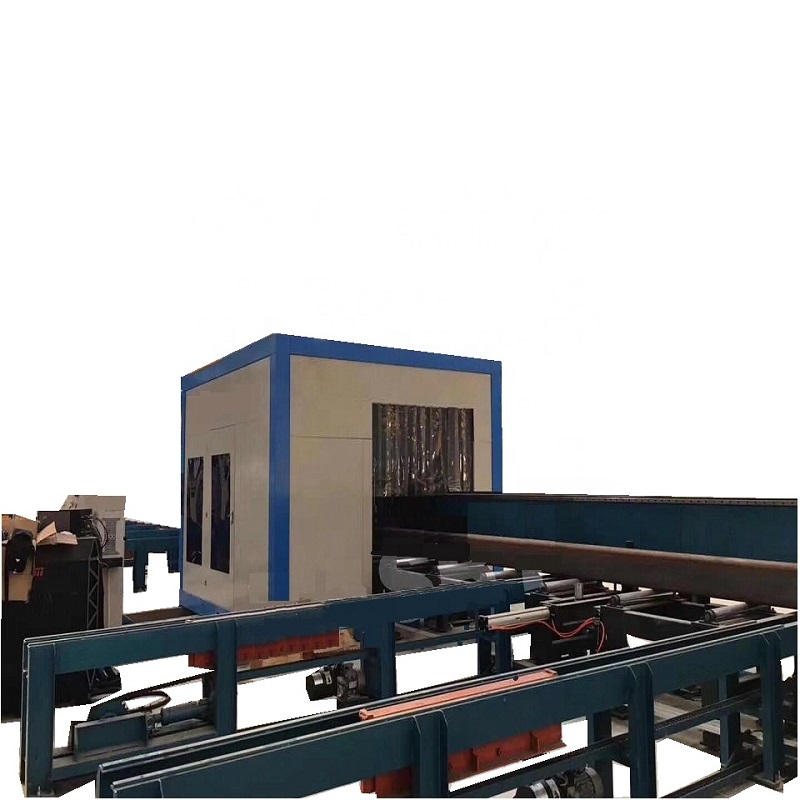

Flame and plasma cutting machine

3D cutting machine

1). Straightening: in the process of steel structure production, due to the deformation of raw materials, cutting deformation, welding deformation, transportation deformation will affect the production and installation of components, correction is to cause new deformation to offset the existing deformation.

2). Bending forming: cold bending forming process methods include roller bending, press bending, top bending, tensile bending, etc.

In the manufacture of steel structure, the internal structure of the steel plate will be changed after shearing or gas cutting the edge. In order to ensure the quality of important components such as steel beams or heavy crane beams, the edges need to be machined.

There are usually two ways to make holes: drilling and punching. Drilling is a common method used in steel structure fabrication.

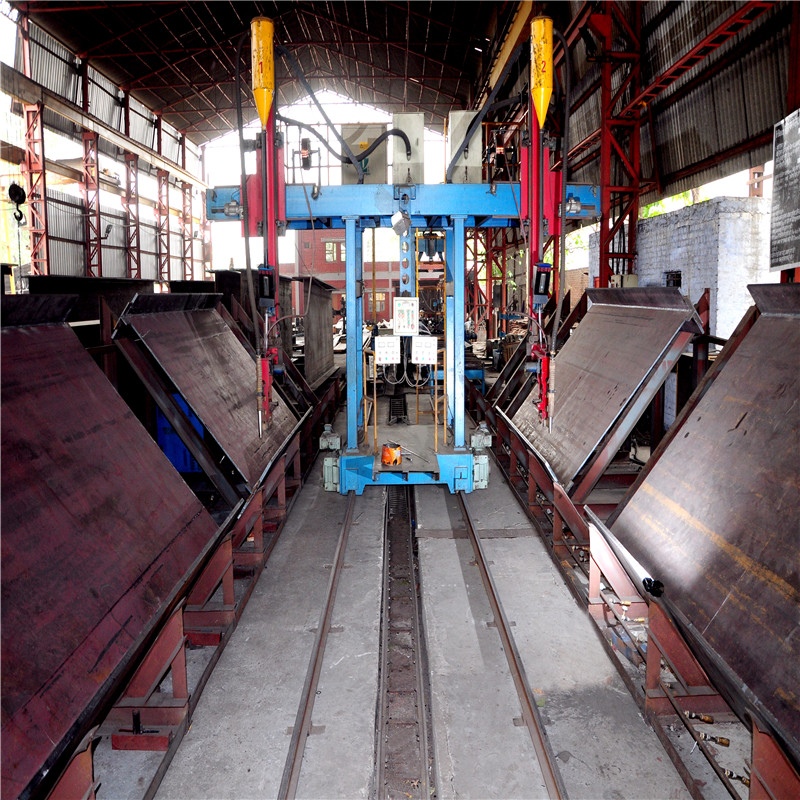

Assembly is to assemble the processed parts into a single component according to the requirements of the construction drawing.

Welding is one of the main joining methods used in steel structures.

High strength bolt connection is one of the main connection methods of steel structure parallel with welding at present, which is characterized by convenient construction, detachable and replaceable, uniform force transfer, good joint rigidity, large bearing capacity, high fatigue strength, nut is not easy to loose, safe and reliable structure.

Sign up for our newsletter to receive the latest news.

Copyright © 2020 WINCOO ENGINEERING CO.,LTD

Support By:Leadong